PC vs Nylon vs Nylon CF: Which Filament Should You Actually Use?

When you move beyond PLA, choosing the right high-performance filament can get confusing fast.

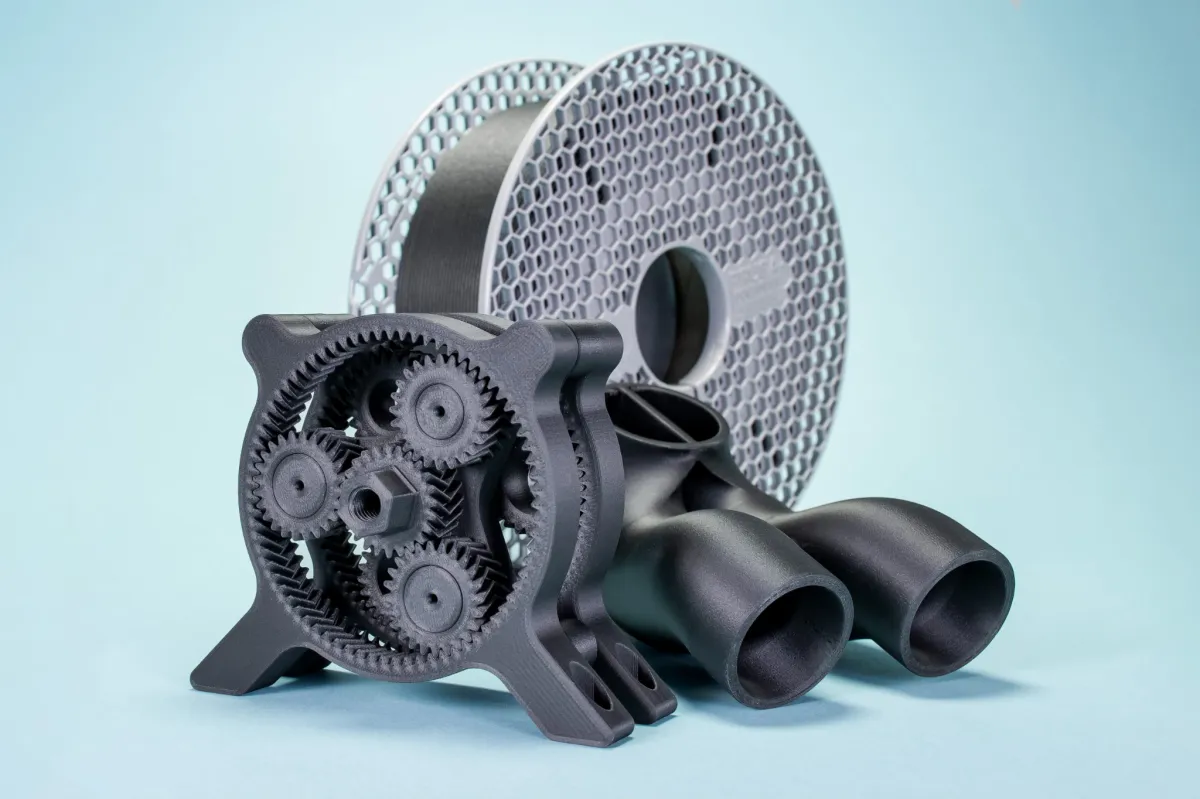

PC, Nylon, and Carbon Fiber-filled Nylon each have their own advantages, print challenges, and ideal use cases.

If you pick the wrong one, you’ll waste time, filament, and maybe even damage your printer.

This guide explains what each material is good for, what to avoid, and how to print them properly.

Polycarbonate (PC): Strength and Heat Resistance

When to use it:

PC is the go-to material when you need parts that can take heat and impact. It performs well at temperatures up to 120°C, making it ideal for mechanical housings, brackets, and enclosures near engines or motors.

Pros:

Extremely strong and impact resistant

Handles high temperatures

Good transparency (depending on formulation)

Cons:

Prone to warping and cracking

Needs an enclosure and heated bed

Prints best with a hardened nozzle

Best use cases:

Automotive mounts, electrical housings, and mechanical brackets where PLA or PETG would deform.

Nylon (PA): Toughness and Wear Resistance

When to use it:

Nylon is best for functional parts that need to handle stress, friction, and wear.

It’s not rubbery flexible like TPU. Instead, it’s tough, durable, and can bend slightly without breaking.

Pros:

High wear resistance

Slight flexibility under load (absorbs impact well)

Works for moving parts and gears

Cons:

Highly hygroscopic (absorbs moisture fast)

Needs drying before and during printing

Warps if printed without an enclosure

Best use cases:

Gears, hinges, spacers, tool handles, and mechanical linkages that experience motion or vibration.

Carbon Fiber Nylon (PA CF): Rigidity and Dimensional Accuracy

When to use it:

CF-filled Nylon combines the durability of Nylon with the stiffness of carbon fiber.

It’s ideal for strong structural parts that need to stay dimensionally stable under stress.

Pros:

Very stiff and stable

Lower warping than plain Nylon

Excellent surface finish

Cons:

Abrasive to brass nozzles (use hardened steel)

Slightly more brittle than standard Nylon

Costs more per kilogram

Best use cases:

Functional prototypes, drone or robot parts, jigs, and fixtures that need strength without metal machining.

Printing Tips for High-Temp Filaments

Always dry your filament before printing.

Keep the print chamber warm and enclosed to prevent warping.

Use strong bed adhesion like a PEI or textured sheet.

Monitor the first layers carefully before leaving a long print unattended.

These materials reward proper setup. Once you get the tuning right, they produce professional-grade parts that outperform basic plastics.

Final Thoughts

Choosing between PC, Nylon, and CF-Nylon comes down to what your part actually needs:

PC for heat and impact

Nylon for toughness and wear

Nylon CF for stiffness and precision

If your prints keep failing or warping, the issue is usually not the filament but the setup.

Get your environment under control and these materials will open the door to real manufacturing-level 3D printing.

At Miloshev Machinery, we use high-temperature materials to produce durable, accurate parts for industrial and robotics applications.

If you want consistent, production-ready prints, the right filament choice is where it starts.