Batch Printing Strategies: Reduce Failures and Downtime

Running multiple 3D printers sounds great in theory.

You hit print, walk away, and wake up to a pile of finished parts.

Reality check: that only happens if you have solid batch printing strategies in place.

Without a plan, batch printing can turn into wasted filament, hours of downtime, and a massive headache.

Let’s break down how to batch print smarter, not harder.

What is Batch Printing?

Batch printing means producing multiple parts at once, either on one build plate or across several machines.

It’s one of the fastest ways to scale production, especially for print farms that need consistent output every day.

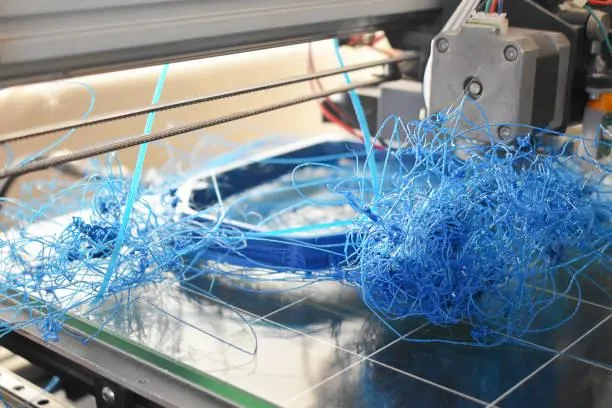

But it comes with risks.

If one part fails mid-print, it can knock into the others, drag them off the bed, and ruin the whole batch.

That’s why optimization and control are everything.

1. Start Small and Scale Up

Never start with full plates of parts you haven’t tested.

Run a small batch first, usually 2 to 3 pieces, and see how the print behaves.

Look for warping, adhesion issues, or inconsistent extrusion.

Fix those before moving on to a large run.

Once you’ve done that, you’ll know exactly how your machine and filament react under longer prints.

2. Group by Reliability, Not Material

Many people group prints by material type. That makes sense at first, but reliability matters more.

If one file is known to fail often, it can ruin every other part in the same batch.

Group models that have already proven themselves reliable.

This small change alone can save hours of wasted print time every week.

3. Schedule Batches Like Shifts

Treat your print farm like a small factory.

Run stable, low-risk jobs overnight and handle experimental or complex parts during the day when you can monitor them.

This prevents wasted hours and keeps machines running efficiently.

For example, a Miloshev Machinery production setup might run high-volume repeat jobs through the night and switch to prototype work in the morning once an operator is present.

4. Keep the Environment Controlled

Batch printing consistency depends on stability.

Humidity, temperature swings, and dust can easily affect adhesion and print quality.

Use enclosed printers where possible, keep filament dry, and maintain a clean workspace.

Even minor improvements to your print environment can dramatically reduce failure rates.

5. Use Automation and Monitoring Tools

Modern 3D printing software can track job progress, detect errors, and even switch spools automatically when filament runs low.

A few key tools and practices worth adopting:

Fleet management software to monitor multiple printers

Cameras for live print tracking

Power recovery and filament run-out sensors

Maintenance logs for each printer

These systems reduce downtime and give you real-time control over every batch.

6. Record Every Failure

Data is your best weapon against downtime.

Whenever a print fails, record what went wrong: bed adhesion, temperature drop, filament issue, or design flaw.

Over time, this data becomes a pattern you can analyze and fix permanently.

At Miloshev Machinery, every print farm setup is built around traceability. We track print times, machine uptime, and common failure points to continuously improve performance.

7. Design for Batch Printing

Not every model is ideal for batch runs.

Avoid designs that have overhangs, tall unsupported sections, or small footprints that might detach mid-print.

When possible, design your parts with a larger contact area or add small brims to help with adhesion.

Even small geometry tweaks can make a big difference when printing 20 or more parts at once.

The Goal: Predictable Production

Batch printing is not just about pushing machines to their limits.

It’s about running predictable, repeatable production with minimal human intervention.

Once you nail your setup, you can scale to 10 or 20 printers without multiplying your problems.

That’s how professional print farms operate, and that’s what separates hobby setups from real manufacturing systems.

Batch printing is powerful when done right.

It saves time, increases output, and turns idle machines into profit-generating assets.

The key is process discipline: test small, monitor closely, automate where possible, and keep learning from every print.

At Miloshev Machinery, we build and optimize 3D printing systems for reliable production.

Whether you’re running two printers or twenty, the goal is the same — consistent output, zero waste, and maximum uptime.