Frequently Asked Questions

Find quick answers to the most common questions about our materials, lead times, and ordering process.

What materials are available?

We print with industrial-grade materials including PLA, PETG, ABS, ASA, TPU, and PA12 — covering everything from simple prototypes to functional, high-strength components.

How do I get a quote?

Shoot us a message at [email protected] or use the contact form below. Attach your STL, STEP, or OBJ files and we’ll get back to you with pricing and lead time within 24 hours.

Do you offer bulk or production discounts?

Yes, we provide scaled pricing for batch runs, recurring orders, and long-term clients. Just mention your quantity when requesting a quote.

Where do you ship from?

All parts are produced and shipped directly from Schleswig, Germany. We deliver across the World with reliable, tracked shipping.

What’s your typical turnaround time?

Most orders are completed and shipped within 1–3 business days, depending on size and complexity. Larger production runs are scheduled individually.

Can I request custom materials or colors?

Absolutely, if you need a specific filament or color, we can order it in for your project. Just let us know in your quote request.

What tolerances can I expect?

Our FDM prints maintain ±0.2 mm dimensional accuracy, depending on part geometry and material. If you need tighter tolerances, just include that note in your quote request.

Do you offer resin or CNC machining?

Not yet, we currently focus entirely on FDM production to guarantee top reliability and speed. CNC and resin capabilities are planned for future expansion.

Can you help me improve my design before printing?

Yes. Every file is manually reviewed before printing, and we’ll reach out if we spot issues or ways to improve strength, fit, or surface finish. We don’t just print, we make sure your part works.

Turn your CAD files into real parts

Upload your files and get a fast, accurate quote for manufacturing. No back and forth. We review your design and handle production from start to finish.

Why ESD-Safe 3D Printing Materials Matter and When You Actually Need Them

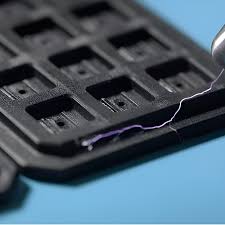

Most people don’t think about static electricity until something stops working. In electronics manufacturing, static discharge is one of the fastest ways to silently destroy components. And the worst part is that it often leaves no visible damage. The part looks fine. The device fails later.

Standard plastics are insulators. They store electrical charge. That makes normal 3D printed parts dangerous around sensitive electronics, PCBs, sensors, and semiconductors. This is where ESD-safe 3D printing materials come in.

They are not marketing hype. They solve a real industrial problem.

What is ESD and why does it matter?

Electrostatic discharge happens when two materials exchange electrical charge and that charge suddenly releases. In electronics, that discharge can be enough to destroy microchips, weaken components, or reduce product lifespan without immediate failure.

If you are working with:

PCBs

Sensors

Microcontrollers

Robotics electronics

Test fixtures

Then static is already part of your risk profile.

What makes ESD-safe materials different

Normal plastics like PLA, PETG, ABS, and Nylon are electrical insulators. They allow charge to build up.

ESD-safe plastics are engineered to slowly dissipate charge instead of storing it. They sit in a controlled middle zone between:

Insulators that trap charge

Conductors that dump charge instantly

This controlled dissipation protects sensitive components without creating new hazards.

How ESD 3D printing materials work

These materials contain conductive additives mixed into the plastic:

Carbon fibers

Carbon nanotubes

Conductive fillers

These additives form microscopic conductive paths through the material that allow static electricity to flow out safely.

The result is a plastic that still behaves mechanically like a polymer but electrically behaves in a controlled, predictable way.

Where ESD 3D printing is actually useful

This is not for decoration. This is for real industrial applications:

PCB holders and assembly fixtures

Electronics enclosures and housings

Static-safe tool organizers

Test rigs and measurement fixtures

Robotics end-of-arm tooling in electronics assembly

Cleanroom components

Part trays for sensitive components

Instead of buying expensive machined ESD tooling, you can print custom parts that fit your exact process.

When does ESD 3D printing make sense?

Use ESD materials if:

Your part touches electronics

Your part holds PCBs

Your part is used in electronics assembly

Your environment requires static control

Your tooling needs fast iteration

Do not use ESD materials if:

The part never interacts with electronics

Static discharge is not a concern

You only need decorative or structural parts

They cost more than standard filaments. Use them where they solve a real problem.

ESD vs normal plastic parts

Normal plastic:

Cheaper

Easier to print

Electrically unsafe for electronics

ESD plastic:

Slightly higher cost

More industrial printing requirements

Protects sensitive components

Enables professional manufacturing workflows

This is the difference between hobby printing and manufacturing printing.

Printing considerations

ESD materials are more abrasive than standard plastics. They usually require:

Hardened steel nozzles

Slightly slower print speeds

Proper drying and storage

Consistent quality control

That is the price of industrial reliability.

Why this matters for modern manufacturing:

Electronics are getting smaller, more sensitive, and more integrated into every product. At the same time, companies want faster development and lower tooling cost.

ESD-safe 3D printing sits exactly at that intersection:

Custom tooling

Low-volume production

Fast iteration

Static protection

It gives you manufacturing speed without sacrificing electronics safety.

If your workflow includes sensitive components, ignoring static protection is gambling with reliability.

We offer ESD-safe 3D printing for custom parts, fixtures, and enclosures.

Upload your file, choose your material, and get a real quote in minutes on this page: https://miloshevmachinery.com/quote