Frequently Asked Questions

Find quick answers to the most common questions about our materials, lead times, and ordering process.

What materials are available?

We print with industrial-grade materials including PLA, PETG, ABS, ASA, TPU, and PA12 — covering everything from simple prototypes to functional, high-strength components.

How do I get a quote?

Shoot us a message at [email protected] or use the contact form below. Attach your STL, STEP, or OBJ files and we’ll get back to you with pricing and lead time within 24 hours.

Do you offer bulk or production discounts?

Yes, we provide scaled pricing for batch runs, recurring orders, and long-term clients. Just mention your quantity when requesting a quote.

Where do you ship from?

All parts are produced and shipped directly from Schleswig, Germany. We deliver across the World with reliable, tracked shipping.

What’s your typical turnaround time?

Most orders are completed and shipped within 1–3 business days, depending on size and complexity. Larger production runs are scheduled individually.

Can I request custom materials or colors?

Absolutely, if you need a specific filament or color, we can order it in for your project. Just let us know in your quote request.

What tolerances can I expect?

Our FDM prints maintain ±0.2 mm dimensional accuracy, depending on part geometry and material. If you need tighter tolerances, just include that note in your quote request.

Do you offer resin or CNC machining?

Not yet, we currently focus entirely on FDM production to guarantee top reliability and speed. CNC and resin capabilities are planned for future expansion.

Can you help me improve my design before printing?

Yes. Every file is manually reviewed before printing, and we’ll reach out if we spot issues or ways to improve strength, fit, or surface finish. We don’t just print, we make sure your part works.

Turn your CAD files into real parts

Upload your files and get a fast, accurate quote for manufacturing. No back and forth. We review your design and handle production from start to finish.

When to Use an Open Printer, an Enclosure, or a Heated Chamber (And Why It Depends on the Plastic)

The biggest mistake people make is thinking printer type comes first. It doesn’t.

The plastic comes first. The printer setup is just there to support the physics of that material.

Every plastic shrinks when it cools. The hotter the plastic prints, the more it shrinks. If cooling happens unevenly, internal stress builds up. That stress becomes warping, cracking, and weak layer bonding. Everything about open printers, enclosures, and heated chambers exists to control how that cooling happens.

The question is not “Which printer is better?”

The question is “How sensitive is this plastic to temperature changes?”

For low-temperature plastics, an open printer is completely fine.

PLA, PETG, and TPU simply do not generate enough thermal stress to justify enclosure or chamber heating. They print at lower nozzle temperatures, shrink very little, and cool evenly in normal room air. An open printer is cheaper, simpler, faster to work with, and already delivers excellent results.

If you mostly print:

PLA

PETG

TPU

Then an open printer is not a compromise. It is the correct tool.

Things change when you step into higher-temperature polymers.

ABS and ASA are where an enclosure starts to matter. These materials shrink much more and hate cold air. Drafts, open rooms, or uneven cooling will cause warping and layer separation. But they usually do not need an actively heated chamber. What they need is a stable environment.

An enclosure traps the heat from the bed and hotend and raises the air temperature naturally. That passive warming is usually enough to keep ABS and ASA stable. The key is not hitting a specific chamber temperature, it is eliminating cold airflow and sudden temperature drops.

For ABS and ASA:

An enclosure is the requirement.

A heated chamber is optional.

Nylon moves you closer to true chamber heating.

It shrinks more, bonds better when warm, and loses mechanical performance if the ambient temperature drops too fast. An enclosure helps, but for consistent strength and dimensional accuracy, active chamber heating becomes valuable. This is where a heated chamber starts making practical sense.

Polycarbonate is even more demanding.

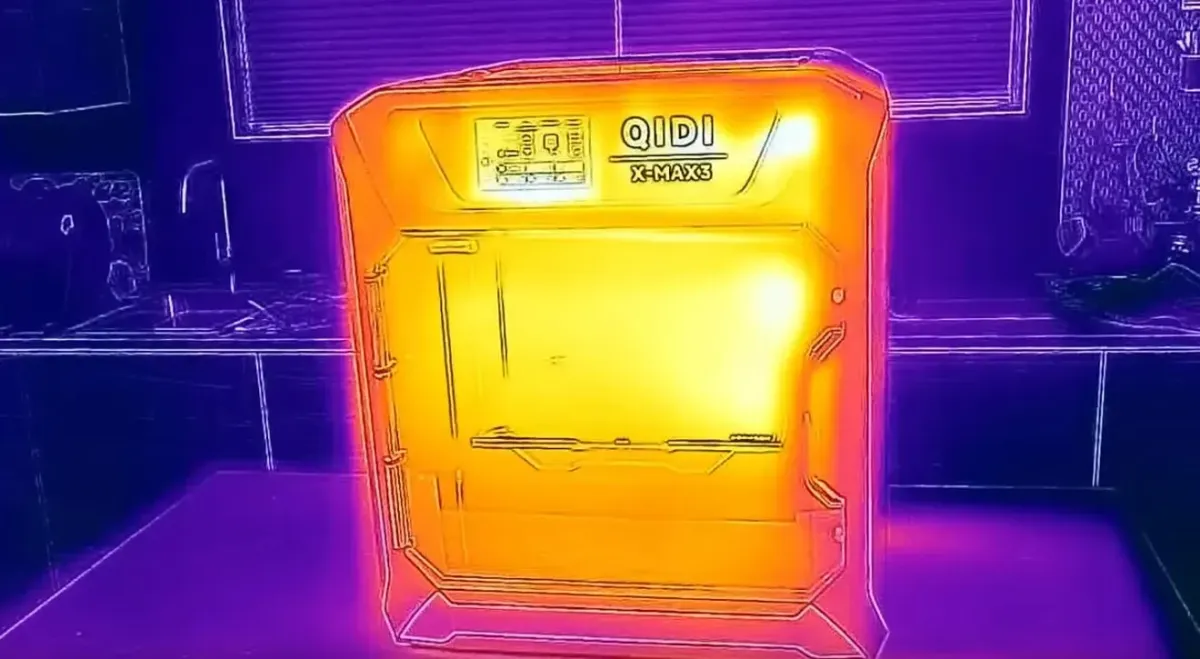

It prints extremely hot and shrinks aggressively. Layer adhesion depends heavily on ambient temperature. At this point, a simple enclosure often isn’t enough. A heated chamber becomes close to mandatory for reliable results.

PEEK and PEI are in a completely different category.

These are industrial polymers that require:

Very high nozzle temperatures

Very hot beds

And a strictly controlled heated chamber

Without active chamber heating, printing them is not realistic in any reliable way.

So the real decision structure looks like this:

Open printer

For materials that barely care about thermal stability.

PLA, PETG, TPU.

Enclosed printer

For materials that need stability but not strict temperature control.

ABS, ASA.

Heated chamber

For materials that need controlled ambient temperature.

Nylon, Polycarbonate, PEI, PEEK.

This is why a heated chamber is not an upgrade path.

It is not “better”.

It is more specialized.

If your parts are cosmetic, prototypes, housings, or light mechanical components made from PLA, PETG, or TPU, an open printer is exactly what you want.

If your parts are structural, outdoors exposed, or need the properties of ABS or ASA, then an enclosure becomes the smart investment.

If your parts require real engineering plastics like Nylon, PC, or anything above that, a heated chamber stops being optional and starts being mandatory.

The printer should always be chosen to serve the material.

Not the material chosen to match the printer.

If you are unsure which material or printer setup fits your part, that is exactly what we help with.

We work with open, enclosed, and heated-chamber capable systems depending on what your application actually needs.

You don’t have to guess. You just upload your file.

Upload your model, select your material, and get a real quote for your part in minutes.