Frequently Asked Questions

Find quick answers to the most common questions about our materials, lead times, and ordering process.

What materials are available?

We print with industrial-grade materials including PLA, PETG, ABS, ASA, TPU, and PA12 — covering everything from simple prototypes to functional, high-strength components.

How do I get a quote?

Shoot us a message at [email protected] or use the contact form below. Attach your STL, STEP, or OBJ files and we’ll get back to you with pricing and lead time within 24 hours.

Do you offer bulk or production discounts?

Yes, we provide scaled pricing for batch runs, recurring orders, and long-term clients. Just mention your quantity when requesting a quote.

Where do you ship from?

All parts are produced and shipped directly from Schleswig, Germany. We deliver across the World with reliable, tracked shipping.

What’s your typical turnaround time?

Most orders are completed and shipped within 1–3 business days, depending on size and complexity. Larger production runs are scheduled individually.

Can I request custom materials or colors?

Absolutely, if you need a specific filament or color, we can order it in for your project. Just let us know in your quote request.

What tolerances can I expect?

Our FDM prints maintain ±0.2 mm dimensional accuracy, depending on part geometry and material. If you need tighter tolerances, just include that note in your quote request.

Do you offer resin or CNC machining?

Not yet, we currently focus entirely on FDM production to guarantee top reliability and speed. CNC and resin capabilities are planned for future expansion.

Can you help me improve my design before printing?

Yes. Every file is manually reviewed before printing, and we’ll reach out if we spot issues or ways to improve strength, fit, or surface finish. We don’t just print, we make sure your part works.

Turn your CAD files into real parts

Upload your files and get a fast, accurate quote for manufacturing. No back and forth. We review your design and handle production from start to finish.

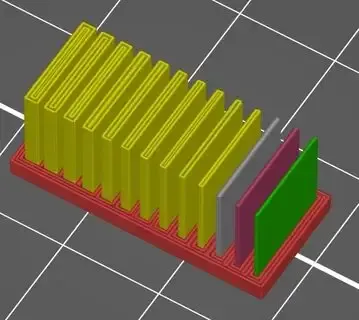

Wall Thickness Guidelines for FDM Parts

Wall thickness is one of the most overlooked settings in 3D printing.

It directly affects strength, print time, and reliability.

Getting it wrong leads to weak walls and failed parts.

Getting it right creates durable prints that perform exactly as intended.

Why Wall Thickness Matters

In FDM printing, walls are the outer perimeters of each layer.

They define the part’s strength and surface finish, while the infill provides internal support.

Thin walls flex and split under stress.

Thick walls waste material and increase print time with little benefit.

The goal is balance. You want walls that are thick enough to carry load but efficient enough to print quickly and accurately.

Recommended Wall Thickness

For general printing, 1.2 mm walls are a solid baseline.

That equals three perimeters with a 0.4 mm nozzle and gives enough strength for most everyday parts.

If your part needs to handle mechanical stress, increase the thickness.

Between 2 and 3 mm is ideal for functional components such as brackets, mounts, or mechanical housings.

For decorative or lightweight parts, you can drop to 0.8 or 1.0 mm, but be aware that thinner shells reduce durability.

Match Wall Thickness to Nozzle Size

Wall thickness should always be a multiple of your nozzle diameter.

Examples:

0.4 mm nozzle → 0.8 mm, 1.2 mm, 1.6 mm

0.6 mm nozzle → 1.2 mm, 1.8 mm

0.8 mm nozzle → 1.6 mm, 2.4 mm

This ensures the slicer generates even perimeters without gaps or uneven extrusion.

Layer Bonding and Strength

The strength of a part depends on how well those walls fuse together.

Proper extrusion temperature, speed, and overlap are more important than high infill.

Most of the mechanical strength in FDM parts comes from the outer shell, not the internal pattern.

Tune your print temperature and extrusion flow until perimeters look consistent, smooth, and fully bonded.

Avoid Single-Wall Prints for Functional Use

Single-wall shells can look fine, but they have almost no strength.

They are suited only for artistic or visual models.

For functional parts, always use at least two perimeters.

It doubles the surface bonding and helps absorb impact or torsion.

Reinforce Stress Points

Thin bridges, holes, and sharp corners are common failure points.

Add extra perimeters or local infill density in those areas.

Modern slicers allow regional adjustments, so you can strengthen critical sections without wasting material across the entire part.

Wall thickness defines print quality, strength, and how your part behaves under stress.

Get it right, and even simple materials like PLA can produce strong components.

At Miloshev Machinery, we design and print FDM parts for industrial use all the time.

If your prints keep failing or you want your prototypes built to production standards, contact us and let’s make it right.

📩 Get in touch with us today to optimize your parts for real-world strength and consistency.