Frequently Asked Questions

Find quick answers to the most common questions about our materials, lead times, and ordering process.

What materials are available?

We print with industrial-grade materials including PLA, PETG, ABS, ASA, TPU, and PA12 — covering everything from simple prototypes to functional, high-strength components.

How do I get a quote?

Shoot us a message at [email protected] or use the contact form below. Attach your STL, STEP, or OBJ files and we’ll get back to you with pricing and lead time within 24 hours.

Do you offer bulk or production discounts?

Yes, we provide scaled pricing for batch runs, recurring orders, and long-term clients. Just mention your quantity when requesting a quote.

Where do you ship from?

All parts are produced and shipped directly from Schleswig, Germany. We deliver across the World with reliable, tracked shipping.

What’s your typical turnaround time?

Most orders are completed and shipped within 1–3 business days, depending on size and complexity. Larger production runs are scheduled individually.

Can I request custom materials or colors?

Absolutely, if you need a specific filament or color, we can order it in for your project. Just let us know in your quote request.

What tolerances can I expect?

Our FDM prints maintain ±0.2 mm dimensional accuracy, depending on part geometry and material. If you need tighter tolerances, just include that note in your quote request.

Do you offer resin or CNC machining?

Not yet, we currently focus entirely on FDM production to guarantee top reliability and speed. CNC and resin capabilities are planned for future expansion.

Can you help me improve my design before printing?

Yes. Every file is manually reviewed before printing, and we’ll reach out if we spot issues or ways to improve strength, fit, or surface finish. We don’t just print, we make sure your part works.

Turn your CAD files into real parts

Upload your files and get a fast, accurate quote for manufacturing. No back and forth. We review your design and handle production from start to finish.

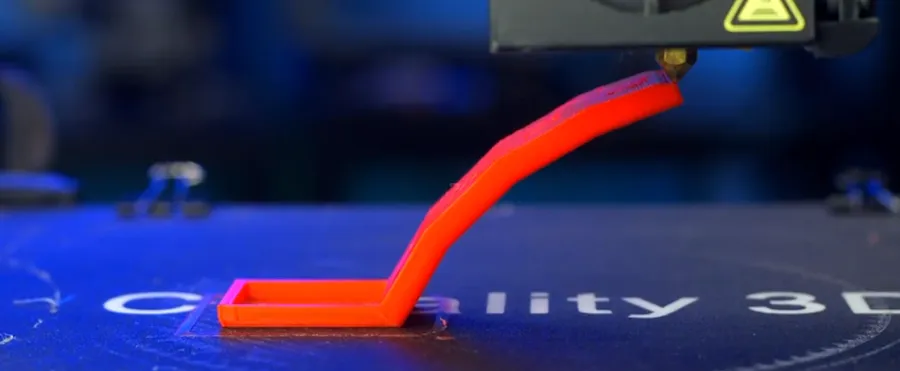

Bed Leveling Is Not Calibration. And Mixing Them Up Is Why Prints Still Fail

One of the biggest misconceptions in 3D printing is thinking that bed leveling and calibration are the same thing. They are not even close. They solve different problems, at different stages of the print, and confusing them is why many printers feel inconsistent.

You can level your bed before every print and still have bad parts.

Because leveling does not make a printer accurate. It only makes the first layer possible.

Calibration is what makes the printer behave correctly.

Understanding that separation changes everything.

What does bed leveling do

Bed leveling is about geometry. Nothing else.

Its only job is to make sure the nozzle has the same distance to the build plate everywhere. That distance defines whether:

The first layer sticks

The filament is squished correctly

The print even starts

Once the first layer is down, bed leveling has already finished its job.

It does not affect:

Wall thickness

Extrusion accuracy

Dimensional accuracy

Layer bonding

Part strength

Bed leveling is a setup step, not a quality tuning step.

What does calibration do

Calibration is about accuracy and consistency.

It makes sure that what the slicer asks for is what the machine actually does.

When the slicer says:

Move 10 mm → the printer really moves 10 mm

Extrude 5 mm of filament → the printer really extrudes 5 mm

Print at 220°C → the plastic behaves as expected

This is what controls:

Wall thickness

Strength

Surface quality

Dimensions

Repeatability

Calibration is what turns a printer from “working” into “reliable”.

Why a leveled bed can still give bad prints

Because leveling only affects the first layer.

You can have a perfect first layer and still get:

Over or under extrusion

Weak layer adhesion

Wrong dimensions

Inconsistent walls

All of those live inside calibration, not leveling.

That is why people get stuck in a loop of re-leveling when the real issue is that the printer itself is slightly out of tune.

How often you should level the bed

Bed leveling should only be done when something mechanical changes.

You should re-level when:

You change the nozzle

You remove or replace the build plate

You crash the nozzle into the bed

You change Z offset

The first layer suddenly becomes uneven

If your first layer looks clean and consistent, your bed is already leveled.

Re-leveling again will not improve print quality.

How often you should calibrate

Calibration should be done:

When you set up a printer for the first time

When you change hardware (hotend, extruder, motors)

When you change filament type

When accuracy or strength matters

Calibration is not something you redo every day, but it is also not a one-time process.

It evolves with your machine and your materials.

How bed leveling is usually done

The goal is always the same: a consistent nozzle gap across the bed.

That is achieved through:

Manual screw leveling

Z offset tuning

Automatic mesh leveling

You know leveling is correct when the first layer is:

Even

Smooth

Slightly squished

Identical across the entire bed

Once that is achieved, leveling is finished.

How calibration is usually done

Calibration is a chain. Each step depends on the previous one being correct.

First comes motion calibration.

The printer must move the right distance in X, Y, and Z.

Then extrusion calibration.

The extruder must push the correct amount of filament.

Then flow tuning.

This matches the real filament behavior to slicer assumptions.

Then temperature tuning.

This defines layer bonding and strength.

Then pressure and retraction tuning.

This controls sharp corners, seams, and consistency.

This is why calibration takes time. It is not one setting. It is a system.

Why people confuse leveling and calibration

Bed leveling is visible. You see it immediately in the first layer.

Calibration is invisible. You only see it later in strength, dimensions, and surface quality.

So when something goes wrong, people touch the only thing they know how to touch: the bed.

That creates the illusion that printing is unpredictable, when in reality the printer is just not calibrated.

The simple rule

If the first layer is bad → level the bed.

If the rest of the print is bad → calibrate the printer.

Leveling lets the print start.

Calibration decides whether the part is actually correct.

Once you separate those two in your head, 3D printing stops feeling like guesswork and starts behaving like manufacturing.

If you are unsure whether your print issues come from leveling or from calibration, that is exactly the kind of problem we deal with every day.

We don’t just print parts. We run properly calibrated machines with controlled setups so your parts come out consistent, accurate, and strong. You don’t have to fight your printer or guess which setting is wrong.

Upload your model, choose your material, and get a real quote from a properly tuned production system.